Everything starts with surface prep. From grease, dirt, mill scale, to rust, never coat an unprepared surface. Without proper surface preparation, a coating will not adhere properly to the substrate and the system will fail.

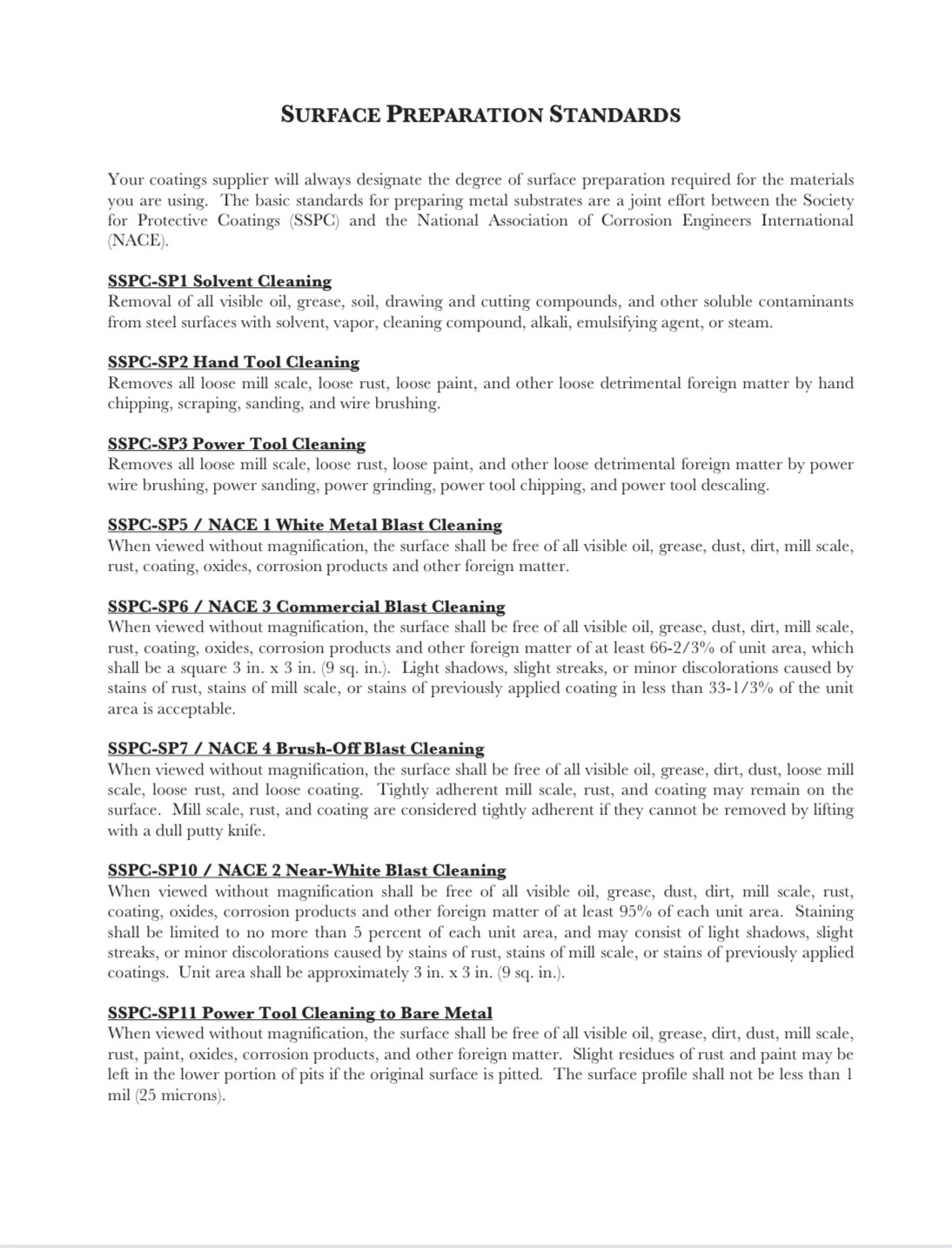

Existing standards — published and continuously revised by independent industry oversight agencies — do a good job of standardizing surface prep outcomes, but naming conventions between agencies can make the standards confusing.

The most commonly accepted standards for contractors and organizations are the NACE International/Society for Protective Coatings (SSPC) Joint Surface Preparation Standards. (NACE and SSPC have recently merged to form AAMP, The Association for Materials Protection and Performance.) While these documents standardize surface prep results and provide a template to meet job specifications, they can be confusing because the numbers, given for each level of surface preparation, don’t always correlate; higher numbers do not necessarily mean a higher degree of surface prep, as one might expect.

Accelerated Industrial Coatings (AIC) was born on the technical and sales side, enjoying the intimate details of each product from a chemistry point of view. We very much enjoy the specifications and systems building process. But it doesn’t stop there, our team is involved in the surface preparation and installation of projects as well. From end-to-end, our design and installation team is involved. We see the whole project through from end to end!